Diameter 11000mm Round Wire Mesh Demister Pad For Absorption Tower

Demister Pad Effect

The gas / vapor containing droplets passes into mesh pad demister

at a predetermined velocity. It easily finds open path through the

mesh but the droplets and mist impinge on the filaments of mesh

where they coalesce and eventually grow to such a size to overcome

surface tension of liquid and force of gravity. Then the liquid

droplets so formed fall down. And the mist free gas / vapour passes

through the mesh demister pad.

Only when there is air space inside the chamber, the vapor-liquid

separator is effective. It can fail either when the mixed stream

inlet is overwhelmed or the draining of collected liquid is slower

than its growing. Considering this, the separator may be combined

with some liquid level sensing accessories, such as a sight glass

or float sensor. By doing this, both the supply and drain flow can

be regulated to prevent the separator from being overloaded.

How The Wire Demister Pad Works

In the chemical process, the gas of various gas-liquid contact

equipment often carries a lot of droplets when leaving the

equipment, such as tower equipment, evaporators, etc. - It is

generally required to separate the droplets entrained in the gas,

so as not to affect the quality of the gas or the operation of the

next process.

Mechanisms for separating droplets or mists from gases include

gravitational settling, inertial collision, centrifugal separation,

diffusional deposition by Brownian motion, and electrostatic

attraction. Wire mesh demister is a typical product in inertial

collision demister, and it is an efficient gas-liquid separation

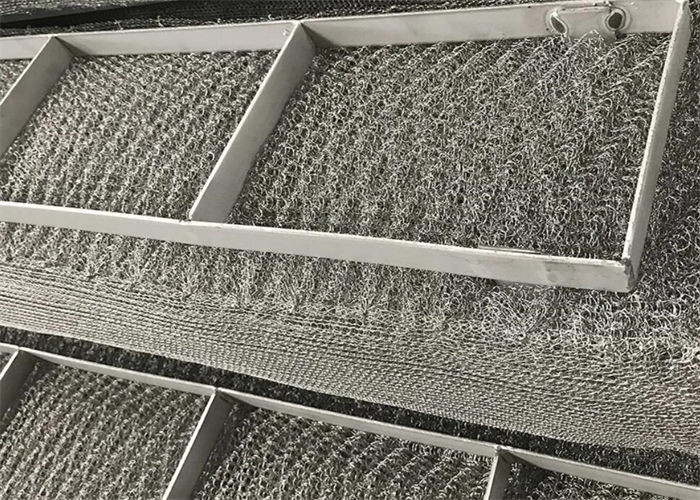

equipment. It has the characteristics of high defoaming efficiency,

simple structure, large void ratio, small pressure drop, light

weight, convenient installation, operation and maintenance.

When the gas passes through the wire mesh demister from bottom to

top, due to the inertial effect, the mist collides with the surface

of the wire mesh, and the mist gathers and expands on the surface

of the filament. When the resultant force of the surface tension of

the liquid, the droplet falls. It is commonly used in towers,

evaporators and separators in industry.

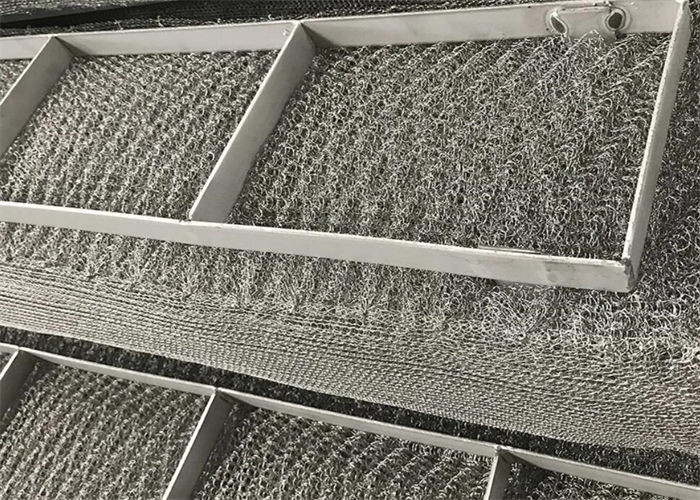

Wire mesh demister mainly by wire mesh, wire mesh grille composed

of blocks and fixed mesh blocks constitute supporting device,

screen for a variety of materials structure and gas demister

installation form Liquid filters, liquid filters are made of metal

wire or non-metallic filaments.

Examples Of Uses Of Wire Mesh Demisters

Wire mesh demisters have been widely used in petroleum refining,

petrochemical, chemical industry, salt industry, electric power

industry, sugar industry, paper industry, electronics industry and

some other synthetic chemical industries. Common tower, tank,

container equipment and other uses are:

1.Vacuum Tower

2. Absorber

3. Knock-0ut Drums

4. Gas Separator Vessels

5. Compressor Suction Drums

6. Evaporator

7. Scrubber

8.Distillation Column

9. Concentrators

10. Dust Collectors

11.EMI Shielding Products

12.Cushion

Company Profile

Anping County Hardware Mesh Products Co., Ltd. is located in Anping

County, Hebei Province, known as the "Hometown of Chinese Wire

Mesh". The company is a dedicated manufacturer of wire mesh

demisters. The company has more than 90 sets of knitted mesh

equipment.The wire mesh demister is the main product of our

company. Most of our employees are operation, maintenance, and

installation personnel with practical experience, who can provide

customers with the required engineering consultation and

installation of tank filtration. solution.Nearly 20 years of

experience in the production of mist eliminator mats, knitted wire

mesh, and other packaging materials.

We have ISO9001 certification and a strict quality control system

in the QC department of the enterprise.

We claim that all mist eliminator pads our customers receive are

qualified and perform perfectly. We have different specifications.

The filtration fineness can reach 3μm~5μm. In addition to standard

and popular sizes, we can also customize specific applications

according to customer needs.

During the company's development, through continuous on-the-spot

inspections, personal exchanges and cooperation with customers, and

comprehensive discounts and technical support, we have won strong

customer support and praise.

The company's performance has maintained an annual output value

growth rate of 30-40. Our employees pursue the policy of

"enterprising, truth-seeking, rigorous and united", continue to

develop and innovate, take technology as the core, and

wholeheartedly provide you with cost-effective products,

high-quality engineering design, and services.

Welcome customer consultation and I sincerely look forward to

cooperating with you!